-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

150L Mixer Tank Pastry Making Equipment Snickers Enrobing Production Line

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | CE ISO9001 |

| Model Number | HTL |

| Minimum Order Quantity | 1 piece |

| Price | Negotiable |

| Packaging Details | Wooden case packing according to your demand |

| Delivery Time | Shipped in 45 work days after payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 15 Piece/Pieces per Month |

| Humidity | 30-55% | Temperature | 18'C--25'C |

|---|---|---|---|

| Material | Stainless Steel | Capacity | Up To 400kg/h |

| Apply | Snicker Bar Producing Line | Warranty | 1 Year |

| High Light | automatic pastry making machine,industrial pastry machine |

||

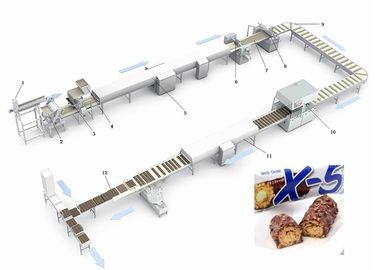

Haitel chocolate Snickers enrobing production line

Haitel chocolate Snickers enrobing production line , 304 stainless steel

Profile:

Snicker bar producing line is applied to the production of the candy bar of caramel, toffee, nut, egg-white candy. The working principle of this line is the automatic production of the full combination between the freezing, forming and pressing rollers and the slitting technology.

COB400 producing line is a multi-function line which is consisted of kitchen equipments, forming and sheeting system, nuts sprinkling system, forming and pressing roller, refrigeration system, cooling tunnel, candy bar slitting, cutting and conveying system, and chocolate enrobing machine etc.. It can produce the bar products in the form of single layer, double layer and filling candy bar etc. as leisure candy food.

This line is designed on the principle of confectionary technology. It is advanced at reliable operation, candy bar forming regulation, wide range of product and convenient maintenance. Especially it takes the place of the traditional manual workshop production with full automatic machinery production. This line will be the first ideal option for the candy bar leisure food industry with modern and large quantity production.

Processing flowchart:

Caramel masses preparation:

Raw materials and ingredients dissolving and mixingà transportingà Storage in the tankà Caramel CookingàMixing with flavorà Discharging à storageà Transporting to the hopper.

Forming and cooling section:

Caramel masses sheetingà conveyingà Pressingà cooling and conveying à Slitting à Cutting à transition conveyingà Chocolate enrobingà Coolingà Packing àfinal products

| S/N | Name | Qty | Remark |

| 1 | Dissolving tank | 1set | 200L |

| 2 | 1” Gear Pump | 1set | 1.1kW |

| 3 | 150L Storage tank | 1set | With stirrer |

| 4 | Caramel masses cooker | 1set | 150kg/h |

| Mixer tank | 1set | 150L | |

| Discharging pump | 1set | 1.5kW | |

| 5 | Cooling table | 1set | Water cooling |

| 6 | Mixing Unit | 1set |

![]()

![]()

![]()