-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

Electric Driven Chocolate Bar Production Line With CE / ISO 9001 Certification

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | CE ISO9001 |

| Model Number | HTL |

| Minimum Order Quantity | 1 Set |

| Price | Negotiable |

| Packaging Details | wooden case package |

| Delivery Time | Shipped in 90 work days after payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 100 Set/Sets per Year |

| Working Conditio | Temp 18 -25 ℃ Humidity 30~55% | Machine Material | Stainless Steel |

|---|---|---|---|

| Driven Type | Electric | Power | 90kw |

| Voltage | 380V 50HZ | Steam Supply | 0.2~0.8 Mpa |

| Capacity | Can Reach 500kg/hr | Compress Air Supply | 0.6Mpa 1.2m³/min |

| Factory Size Require | L>35 M,W>5 M,H>3m | Feature | High Durability |

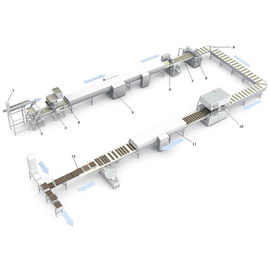

Automatic compound sugar bars and cereal bars forming line

Producing line introduction:

The production line mainly used for the snickers bars with chocolate coating. It improved the traditionalmanual production into full automatic continuously production. This line is completed by the combination of low temperature roll pressing and slitting. Easy to operate and convenient to maintain, our product replaces the traditional artificial molding way with automatic production way and its thus suitable for the modern, large-scale, and intensive production of various filled bars. Such as Snickers, cereal bar, muesli bar etc.

Whole line will be installed total length 50M, width 22.4m,Lenth is 50m, turning diameter is 3.2m.

| Model | |

| Capacity | Can reach 500kg/hr |

| Power Supply | 90 kw 380 V |

| Steam Supply | 0.2~0.8 Mpa 500KG/HR kw 200V/380 V |

| Compress air Supply | 0.6Mpa 1.2m³/min |

| Working condition | Temp 18 -25 ℃;Humidity 30~55% |

| Factory size require | L>35 m,W>5 m,H>3m |

| Total weight | 20500kg |

1. Mixer-continuous or batchwise-for feeding item 2.

2. Slab former type for the first product layer.

3. Slab former type for the second product layer.

4. Sprinkling device for nuts, rice crispies etc.

5. Cooling tunnel,with water cooling from below and air cooling from above.

6. Longitudinal slitter.

7. Combined vertical and horizontal spreading.

8. Guillotine cutter, mechanical or ultrasonic.

9. 90o or 180o turn conveyor.

10. Chocolate coating line.

11. Chocolate cooling tunnel.

12. Collect system for bars.

Flowchart

![]()

![]()

![]()

Quote and Sign firm contract: After confirm with customers with all details, such as payment terms,model, delivery time,send official quotation to clients.