-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

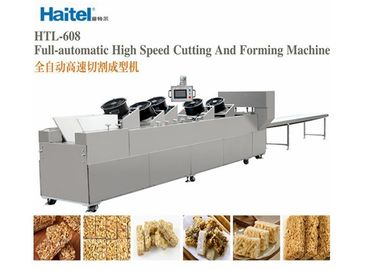

High Efficiency Snacks Production Machines Without Manual Operation

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | ISO 9001:2000 and CE |

| Model Number | HTL-608 |

| Minimum Order Quantity | 1 Set |

| Price | Negotiable |

| Packaging Details | wooden case |

| Delivery Time | 60days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 30 Set/Sets per Month |

| Power(w) | 6KW | Voltage | 380V |

|---|---|---|---|

| Brand Name | HAITEL | Dimension(l*w*h) | 9800*1000*1300mm |

| Certification | ISO 9001 | Weight | 2000kg |

| Application | Snack Food | Type | Fully Automatic |

| High Light | snack food making machine,snacks production machines |

||

Sachima automatic press flat article open piece the production line hot sale 2017

Main Production Process:

Sugar cooking → Mixing sugar and nuts → Elevator transport → Press flat → Cutting → Forming →Packing

Specifications:

| Model | HTL-608B |

| Production capacity | 300-600 kg/h |

| Power | 100 kW |

| Dimension (L*W*H) |

20000*1500*1800 mm |

Features:

- 1. The machine stirring, flatting, and cutting three processes are integrated together, without manual operation, it has realized the real automatic and intelligent operation. Improve the production efficiency, save the human cost.

- 2. Imitate human manual cutting principle, adopts advanced frequency control of motor speed, it can produce different products according to customers’ needs.

- 3. It has many reforming flat structure, flatting smooth, uniform thickness. Cutting speed automatic control, automatic feeding, horizontal, vertical automatic feed cutting food, square size can be customized.

- 4. PLC intelligent computer controlled, convenient and efficient, easy to operate.

- 5. This machine works continuously, no-stop slitting and cutting, improving produce efficiency, the output can reach 2000 pcs/min.

- 6. High speed head of slitting, the length can be adjusted freely, and it has no different length bars and incline phenomenon.

- 7. Spreading materials very uniformly. It uses unequal distance auger to separate all the materials very uniformly.

- 8. The products surface is pressed very smoothly, and the thickness of products is easily to be adjusted.

- 9. The quality of all machines materials is very good. The machine has been reasonable designed.

Our Services

Pre-sale

confirm machine type: Negotiate with clients to seclect the correct machine according to customers‘ requirment.

Quote and Sign firm contract: After confirm with customers with all details, such as payment terms,model, delivery time,send official quotation to clients.

Testing & training:

The plant layout design, assembling, installation and debugging, start-up and local team training will be FREE at no cost. But the buyer should be responsible for the round-air tickets, local transportation, board & lodging, and USD $100/day/person for the pocket money to our technicians. The testing engineer will be two persons, and will cost 7 days.

![]()