All Products

-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

Contact Person :

Chloe

Phone Number :

86-13770276058

WhatsApp :

+8613770276058

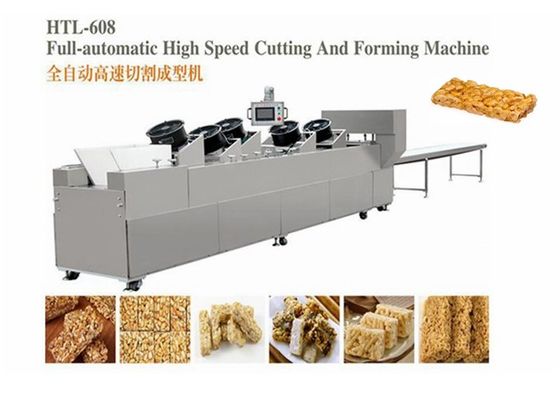

Healthy Peanut Candy Bar Brittle Crisp Making Machine With Microcomputer Control

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | CE ISO9001 |

| Model Number | HTL-608D |

| Minimum Order Quantity | 1 piece |

| Price | Negotiable |

| Packaging Details | Wooden case packing according to your demand |

| Delivery Time | Shipped in 45 work days after payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 100 Set/Sets per Year |

Product Details

| Condition | New | Model Number | 608 |

|---|---|---|---|

| Voltage | 380V/50HZ | Power | 6kw |

| Weight | 2000kg | Dimension(L*W*H) | 9800*1000*1300mm |

| High Light | cereal bar production line,cereal processing equipment |

||

Product Description

Healthy peanut candy bar Brittle Crisp making machine

Main characteristics

1. The three processes of mixing, leveling and cutting are combined, and no human contact is made, realizing automatic automation and intelligent operation. Improve production efficiency and save labor costs.

2, emulate the principle of manual cutting, using advanced motor speed inverter control, different products can meet your needs.

3. It has many reforming plane structures, smooth pressing and uniform thickness. Automatic cutting speed control, automatic feeding, horizontal and vertical automatic feeding and cutting of food, square size can be customized.

4. Microcomputer control, convenient and convenient, easy to operate.

5, the machine continues to work, non-stop cutting, improve production efficiency, the output can reach 2000 pieces / minute.

6, high-speed slitting head can adjust the length of freedom, no length, short rod, tilt phenomenon.

7. The excipients are even, and the products are evenly distributed with an equidistant spiral packaging machine.

8. The surface is calendered, the thickness is adjusted, and the thickness is convenient.

9. The material quality of all machines is very good and the design is reasonable.

Main parameters of the machine

| Material of machine | Stainless steel |

| Output | 200-1000kg/h |

| Voltage | 380V/50HZ |

| Power | 5.5kw |

| Dimension | 8000*1200*1500mm Dimension can custom-made according to requirement |

| Weight | 2000kg |

Product Image

![]()

![]()

![]()

Recommended Products