-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

CE ISO9001 Pastry Making Equipment , Protein Candy Chocolate Nougat Bar Making Machine

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | CE ISO9001 |

| Model Number | HTL |

| Minimum Order Quantity | 1 piece |

| Price | Negotiable |

| Packaging Details | Wooden case packing according to your demand |

| Delivery Time | Shipped in 45 work days after payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 15 Piece/Pieces per Month |

| Weight | Various | Warranty | 1 Year |

|---|---|---|---|

| After-sales Service Provided | Engineers Available To Service Machinery Overseas | Enrober | Selective |

| Condition | New | Applicable Industries | Food & Beverage Factory, Food & Beverage Shops, Confectionery Factory |

| High Light | automatic pastry making machine,industrial pastry machine |

||

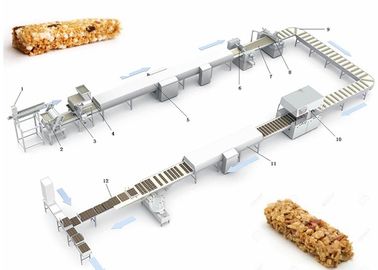

High Quality Protein Candy chocolate Nougat Bar making Machine Production Line

Application

The SWM-BAR series Candy Bar Production Line is dedicated equipment for the production of nougat, snickers, cereal bar, KDV Sweets and so on.

The line has the advantages of high-output, continuous production with rapid changeover, low scrap rates and minimal requirement for operators ensure that unit costs are kept extremely low. The consistent size, shape and weight also contribute to high levels of wrapping efficiency.

Main components

1. Auto-weighing and dissolving system

2. Aerating cooker for nougat

3. Double 'Z' blade mixer

4. Caramel cooker

5. Nougat layer forming roller

6. Caramel layer forming roller

7. Nuts sprinkler(optional)

8. Forming rollers

9. Cooling tunnel

10. Slitter and ropes separating conveyors

11. Guillotine (cross cutting)

12. Enrober and cooling tunnel

13. Flow wrapping machine

Packaging:

The normal package is wooden case(Size: L*W*H). If export to european countries,the wooden case will be fumigated. We will use PE film for packing if container is too tigher, and we can also pack it according to customers special request.

Delivery Time:

150 days after receiving deposit.

![]()

![]()