-

Candy Production Line

-

Chocolate Bar Production Line

-

Snack Food Production Line

-

Cereal Production Line

-

Bakery Production Equipment

-

Automatic Food Packing Machine

-

Candy Packaging Machine

-

Chocolate Packaging Machine

-

Pastry Packaging Machine

-

Candy Forming Machine

-

Candy Cutting Machine

-

Pastry Making Equipment

-

Mask Making Production Line

-

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality.

ThomasMachinery is very good, one-year warranty, life-long service. The machine is of good quality. -

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings.

JamesIt's quite practical. Workers love it. Programs are assembled all by themselves. Knowing machines and NC programs can make it dance. I'm not comfortable with all the data super-permanent settings. -

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

MuktarBeautiful, convenient, atmospheric, real, logistics is also very fast, select a lot of machines, see this, very satisfied, packaging is very hard, strict, vendors sent video, Commissioning Engineer arrangements are also very fast, physical and vendor description of the one-to-one, very grateful to the vendor's thoughtful service. Conscience buyer.

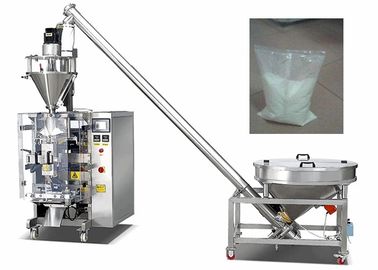

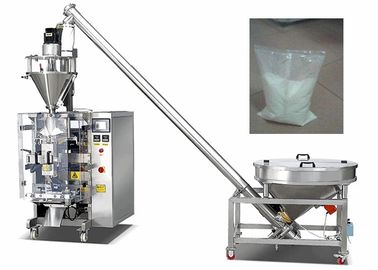

Flour Maize Corn Plantain Powder Packing Machine With PLC Control System

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | Haitel |

| Certification | CE ISO9001 |

| Model Number | HTL-D420 |

| Minimum Order Quantity | 1 piece |

| Price | Negotiable |

| Packaging Details | Wooden case packing according to your demand |

| Delivery Time | Shipped in 45 work days after payment |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 15 Piece/Pieces per Month |

| Warranty | 12 Months | Application | Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Apparel, Textiles, Seaweed Packing Machine |

|---|---|---|---|

| Packaging Material | Plastic, Wood | Condition | New |

| Driven Type | Electric | Voltage | 220V/380V/110V/240V/415V |

| High Light | candy manufacturing machine,hard candy making equipment |

||

Automatic flour maize corn plantain powder packing machine

Product Description

Features:

1. adopts the advanced PLC control system, touch screen in both Chinese and English, and automatic completion of measuring, bag making, filling, sealing, cutting and printing codes.

2. adopts the stainless steel 201 for the machine's mainframe, and stainless steel 304 for the parts touching supplies, which has a very good effect of anti-rusting, so guarantee the products clean and sanitary, and also greatly prolong the machine's life-span.

3. Fully sealed for the machine mainframe, keep the powder supplies clean and sanitary.

Technical Parameters:

| Packing speed | About 30-60 bags/min. It is according to quality of wrapping film and materials. |

| Accuracy | ≤1.5% |

| Bag size | (L) 80-350 mm; (W)100-250 mm |

| Maximum film width | 520 mm |

| Filling range | 150-2000g |

| Film thickness | 0.04-0.09 mm |

| Packing material | Thermal composite materials, such as BOPP/CPP, PET/AL/PE |

| Air consumption | 0.8 MPa, 0.4 m³/min |

| Total power | 5 KW |

| Voltage (V) | Four wires, three phases, 380V, 50Hz. |

| Air compressor | Not less than 1 CBM |

| Total height | 2528 mm |

| Gross weight | 900 kg |

![]()

![]()